Last year was certainly an extraordinary one. The COVID19 pandemic put everything to a halt in the beginning of the year. Electronics and semiconductors bounced back remarkably quickly and now we´re getting back to growth and business as usual, says Ghita Hoyer, the Regional Sales Manager Nordics for Farnell.

Last year was certainly an extraordinary one. The COVID19 pandemic put everything to a halt in the beginning of the year. Electronics and semiconductors bounced back remarkably quickly and now we´re getting back to growth and business as usual, says Ghita Hoyer, the Regional Sales Manager Nordics for Farnell.

Ghita was kind enough to enlighten us about what happened in distribution in 2020 and what we have to expect in 2021.

How has the pandemic changed the market? Has it changed the dynamics?

At the first emergence of the pandemic in spring 2020, the most prominent market change was the demand for medical components. From circuit board components to fans and power supplies for ventilators and respirators, the demand for health care parts and products increased dramatically. As market demand for these parts grew, suppliers and distributors experienced a period of excess demand; the quantity of components demanded by the customers outstripped the supply that any one distributor could stock. Fortunately, due to Farnell’s comprehensive portfolio and long-standing relationships with world-leading suppliers, we accessed additional stock to fulfil orders and support customers as they moved to produce medical equipment at scale.

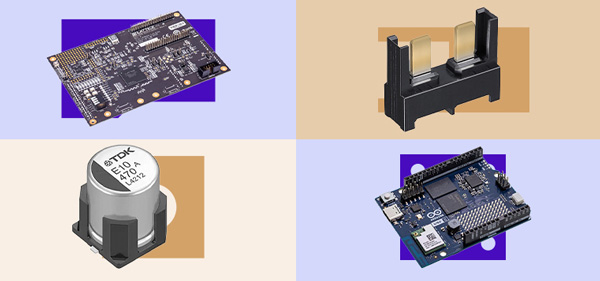

As we progressed through 2020 and into the New Year, the world has grown more accustomed to the virus and industry seeks to return to a more normal trading environment. As such, we are seeing an acceleration of existing trends and demand increasing in segments such as IoT/IIoT, 5G technologies and smart energy. Recent years have shown a trend towards electric vehicles too and in the current market this is increasing once again, especially for cars and scooters, as the population seeks to avoid public transport where the risk of infection is significantly increased.

A final change has been in the purchasing patterns of our customers. We have seen the shift of most employees worldwide, including our own colleagues at Farnell, to a work from home model and a result of this has been an increase in demand outside of normal operating hours. Demand has moved across a much wider time frame and, in complete contrast to buying patterns prior to COVID-19, we now receive significant order quantities early in the morning, late in the evening and even through the night as buyers perform their work remotely, on a time schedule far more flexible than when they were working from the office. We are seeing vaccination programmes begin to rollout across Europe, however we anticipate remote working will continue well into 2021 and we are equipped with the experience and knowledge from the last year to best serve our customers and supplier partners as we all continue to operate from the home office. Even whilst working from home our local language teams continue to provide bespoke service to our customers in Finland and the Farnell business as a whole has widely embraced technology, in particular video conferencing tools such as MS Teams and Zoom, to maintain our local proposition service even as we are unable to visit our customers in person.

According to DMASS, the Nordics (in semiconductors) came down considerably in 2020. Who are the winners/losers? Big broadline distributors? Specialised distributors? Catalogue/online sellers?

Demand in the global semiconductor market has been buoyant for some time now and, despite recent challenges in the Nordics, we anticipate the demand for semiconductors to remain as strong as ever. As the modern world continues to embrace new technologies such as AI, 5G and technologies key to addressing climate change, the demand for semiconductors will continue to accelerate and drive growth even in regions and markets which experienced a more challenging 2020 than previous years.

How did the lead times develope during 2020? Any problem areas? How was Farnell able to cope with this problem?

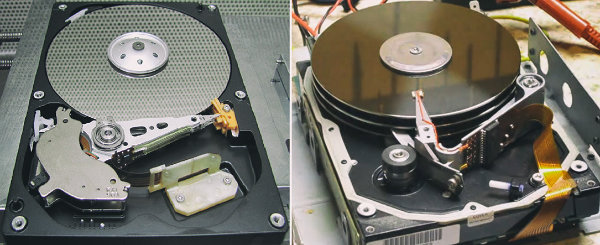

The manufacture of electronic components is a global exercise. Components can be made in one country, tested and packaged in another, then purchased and shipped to a different country for end-use. In 2020, manufacturing was heavily impacted due to the closure of factories during the first spring lockdowns and even in those areas where factories could function, there were still major logistical challenges getting components to reach those factories in the first place, or conversely, getting the finished goods shipped out of the functional factory into another locale.

For suppliers and distributors, transporting large quantities of parts or finished products quickly was a major challenge in 2020 and limitations on flight capacity pushed manufacturers to consider sea or land transportation, adding time to the operation. It is an unfortunate fact of the market that lead times across the board extended in 2020 and we are seeing this continue in early 2021.

As a global distributor with a footprint across 5 continents we have flexed all our operational capacity in order to secure and ship the products our customers require and deliver them at the earliest possible opportunity, even at a time when this has been very challenging logistically.

Have you seen customer projects being cancelled because of the pandemic or just postponing them? Is there a demand building up that is only waiting for business as usual?

It was a natural response for customers to hold back slightly at the beginning of the pandemic; we saw this in almost all sectors of the economy as market uncertainty drives more conservative buying patterns. There were additional considerations for our customers to make from a logistical point of view; many of our customers and their employees had shifted to working from home and budgets were temporarily frozen until the market became more certain. That being said, we saw very few cancellations. In some sectors we even saw growth in customer projects, in particular in those market segments which saw increased demand due to the pandemic such as medical and 5G. Projects in these areas have continued and often accelerated during the pandemic period.

How has Farnell business developed in the Nordics and especially in Finland during 2020? What are your expectations for 2021?

After a challenging time in 2020 with lockdown and restrictions we do see Finland and the rest of the Nordic countries returning to growth, with the last quarter showing an increase in demand and movement for the business towards a more normal trading environment as we settle into the New Year.

We are feeling optimistic for 2021 and have some significant expectations for Farnell, not just in the Nordics but across EMEA. We are nearing completion of our new state-of-the-art distribution centre which will be fully automated and offering major increases to our stocking capability. The investment in this new market-leading facility was part of broader investments made across the business, such as the addition of over 30 new supplier franchises including MPS, Control Techniques and MegiQ, and continued investment in the depth of our proposition, growing our stocking position for suppliers such as Mitsubishi Electric and TE Connectivity.

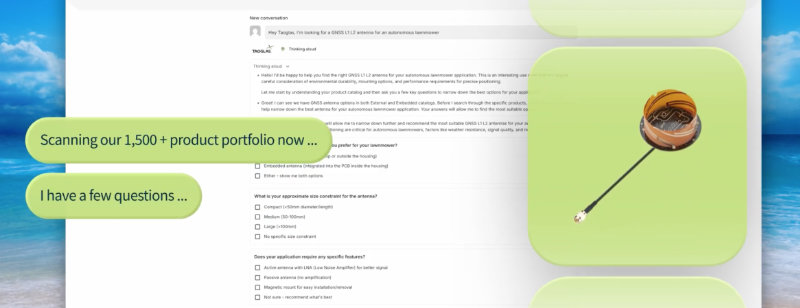

The transactional web platform has also been enriched and further improvements planned for 2021 will drive ever-improving online experience for our customers including more self-service tools and a number of new functionalities. Farnell’s move towards our web platforms is particularly key for us in the Nordics region, especially in Finland, as the desire to buy online is significant and far higher than we see in other regions of the world, with 85-90% ecommerce penetration. These are really positive numbers and customers already purchasing through our transactional websites can expect even better tools, functionality and service in the coming months.

Overall we see a bright 2021; the pandemic and its aftermath will continue to create uncertainty and we know not to rule out the unexpected, but we will continue to invest in our business and our proposition and we look forward serving our customers in Finland and the rest of the Nordics in 2021.

Virtaamamittaus on monissa laitteissa kriittinen mutta usein ongelmallinen toiminto. Perinteiset mekaaniset anturit kuluvat ja jäävät sokeiksi pienille virtausnopeuksille. Ultraäänitekniikkaan perustuvat valmiit moduulit tarjoavat nyt tarkan, huoltovapaan ja helposti integroitavan vaihtoehdon niin kuluttaja- kuin teollisuussovelluksiin.

Virtaamamittaus on monissa laitteissa kriittinen mutta usein ongelmallinen toiminto. Perinteiset mekaaniset anturit kuluvat ja jäävät sokeiksi pienille virtausnopeuksille. Ultraäänitekniikkaan perustuvat valmiit moduulit tarjoavat nyt tarkan, huoltovapaan ja helposti integroitavan vaihtoehdon niin kuluttaja- kuin teollisuussovelluksiin.