Autoteollisuus on siirtymässä yhteen Ethernet-pohjaiseen selkärankaan. Tämä muutos mahdollistaa ajoneuvojen jakamisen "vyöhykkeisiin", joista kukin voi kommunikoida tehokkaasti keskitetyssä laskentaympäristössä IP-pohjaisen ja yleisesti käytössä olevan Ethernet-verkon kautta.

Nykyautojen monimutkaisuus ja innovaatiot heijastavat laajempia teknologian kehitysaskelia. Tämän päivän ajoneuvot toimivat korkean suorituskyvyn laskenta-alustoina, jotka käsittelevät valtavia tietomääriä ja toimivat kuin liikkuvat datakeskukset. Nämä ajoneuvot yhdistävät useita alajärjestelmiä, jotka luottavat saumattomaan tiedonvaihtoon mahdollistamaan automaation, kommunikoiden fyysisen maailman kanssa erilaisten sensoreiden ja toimilaitteiden avulla.

Perinteisesti nämä alajärjestelmät ovat hyödyntäneet kommunikaatioteknologioita, jotka on optimoitu tiettyihin tehtäviin, mikä on johtanut erityisiin laitearkkitehtuureihin. Jokainen toiminnallinen alue vaati oman sovelluskohtaisen viestintäväylänsä tiedonsiirtoon, minkä vuoksi tarvittiin yhdyskäytävätietokoneita muuntamaan tietoa eri järjestelmien välillä. Koska käytössä oli jopa 20 eri verkkostandardia, tämä lähestymistapa lisäsi merkittävästi monimutkaisuutta. Autonvalmistajat etsivätkin yksinkertaisempaa ratkaisua, joka yhtenäistäisi koko ajoneuvon viestintäinfrastruktuurin.

SIIRTYMINEN ETHERNET-POHJAISIIN VYÖHYKEARKKITEHTUUREIHIN

Vastauksena tähän haasteeseen autoteollisuus on siirtymässä yhteen Ethernet-pohjaiseen selkärankaan. Tämä muutos mahdollistaa ajoneuvojen jakamisen "vyöhykkeisiin", joista kukin voi kommunikoida tehokkaasti keskitetyssä laskentaympäristössä IP-pohjaisen ja yleisesti käytössä olevan Ethernet-verkon kautta. Yhteistyössä IEEE:n kanssa autonvalmistajat ovat auttaneet määrittelemään fyysisen kerroksen standardin, joka vaatii vain yhden tasapainoisen johdinparin aiemmin käytettyjen monien johdinparien sijaan.

Siirtyminen Ethernet-pohjaisiin vyöhykearkkitehtuureihin merkitsee merkittävää edistysaskelta ajoneuvosuunnittelussa ja toiminnallisuudessa. Ottamalla käyttöön yhden yhtenäisen viestintäteknologian autonvalmistajat voivat yksinkertaistaa ajoneuvon sisäistä verkkoa, vähentäen monimutkaisuutta ja kustannuksia, jotka liittyvät useiden eri viestintästandardien hallintaan. Tehokkuuden lisäksi tämä muutos parantaa ajoneuvon suorituskykyä ja luo perustan kehittyneemmille toiminnoille.

YHTENÄISEN DATAKEHYKSEN EDUT

Yhtenäinen datakehys (data framework) mahdollistaa ajoneuvon toimintojen ja järjestelmien ohjelmistopohjaisuuden, mikä vähentää viiveitä ja monimutkaisuutta. Kun kyberturvallisuuden merkitys kasvaa, standardoidut todennus- ja salausmenetelmät varmistavat verkon osallistujien ja datan suojauksen. Aiemmat viestintäväylät eivät sisältäneet sisäänrakennettuja turvaominaisuuksia, mikä vaati hajanaisia ja epäyhtenäisiä keinoja turvallisuusuhkien torjumiseksi.

Turvallisuuden ja tehokkuuden lisäksi yhtenäinen tietorakenne yksinkertaistaa uusien teknologioiden ja ominaisuuksien integrointia. Koska autoteollisuus etenee muun muassa autonomisen ajamisen, sähköautojen (EV) ja verkottuneiden autojen teknologioissa, tämä standardointi varmistaa, että uudet innovaatiot voidaan sujuvasti sisällyttää olemassa oleviin arkkitehtuureihin. Lopputuloksena on yhtenäisempi ja tulevaisuuden tarpeisiin valmis ajoneuvoalusta.

Tässä artikkeli kokonaisuudessaan. Koko ETNdigi-lehti löytyy verkossa täältä.

YOUR NEXT CAR WILL RUN ON ETHERNET

The automotive industry is transitioning to a single Ethernet-based backbone. This shift enables vehicles to be divided into "zones," each of which can interact efficiently with a centralized computing platform via an IP-based, ubiquitous Ethernet network.

Henry Muyshondt

Microchip Technology

The complexity and innovation of modern automobiles reflect broader advancements in technology. Today’s vehicles function as high-performance computing platforms, processing vast amounts of data and acting as datacenters on wheels. These vehicles integrate multiple subsystems that rely on seamless information exchange to enable automation, interacting with the physical world through an array of sensors and actuators.

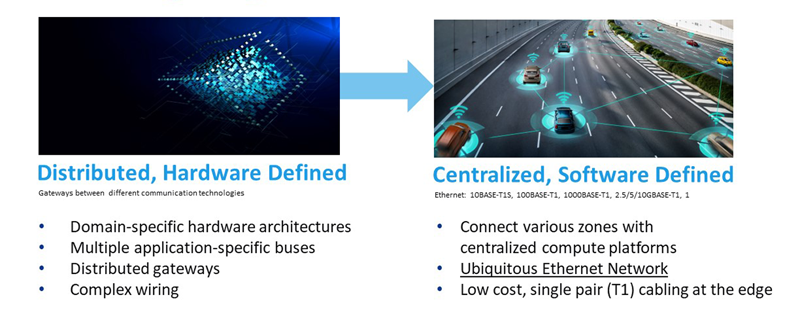

Traditionally, these subsystems employed communication technologies optimized for specific functions, resulting in domain-specific hardware architectures. Each domain required its own application-specific communication bus to transfer data, necessitating the use of gateway computers to translate information between different systems. With as many as 20 networking standards in use, this approach led to significant complexity. Automakers sought a more streamlined solution—one that would unify communication infrastructure across the vehicle.

TRANSITION TO ETHERNET-BASED ZONAL ARCHITECTURES

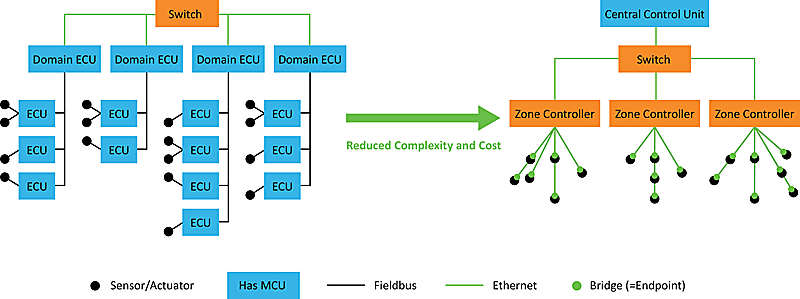

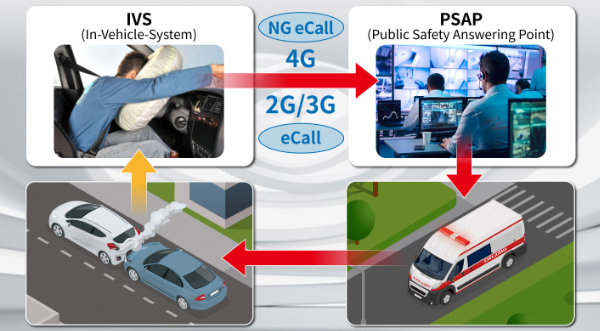

In response to this challenge, the automotive industry is transitioning to a single Ethernet-based backbone. This shift enables vehicles to be divided into "zones," each of which can interact efficiently with a centralized computing platform via an IP-based, ubiquitous Ethernet network. By collaborating with the IEEE, automakers helped define a physical layer standard requiring only a single balanced pair of wires, rather than the multiple pairs historically used in Ethernet installations. Figure 1 illustrates the evolution from domain-specific architectures to zonal architectures with a centralized computing platform.

Figure 1. Networking Megatrend: From Domain-Specific to Zonal Architecture.

This transition to Ethernet-based zonal architectures marks a significant advancement in automotive design and functionality. By adopting a single communication technology, automakers can simplify the vehicle’s internal network, reducing the complexity and cost associated with managing multiple communication standards. Beyond efficiency, this transformation enhances vehicle performance and lays the groundwork for more advanced capabilities.

BENEFITS OF A COMMON DATA FRAMEWORK

A unified data framework enables vehicle functions and systems to be software-defined, reducing latency and complexity. As cybersecurity concerns grow, standardized authentication and encryption mechanisms ensure that network participants and data remain protected. Previous communication buses lacked built-in security features, requiring disparate and inconsistent approaches to mitigate security threats.

Beyond security and efficiency, a common data framework simplifies the integration of new technologies and features. As the automotive industry advances in areas such as autonomous driving, electric vehicles (EVs), and connected car technology, this standardization ensures that new innovations can be smoothly incorporated into existing architectures. The result is a more cohesive, future-ready vehicle platform.

SIMPLIFIED SOFTWARE UPGRADES

A unified network infrastructure simplifies software upgrades by allowing updates to be deployed through a single standardized approach. Previously, different data links required distinct update methodologies, increasing complexity. The ability to deliver seamless software upgrades represents a major advantage for the automotive industry.

As vehicles become increasingly software-driven, frequent updates and enhancements become essential. A common network enables over-the-air (OTA) updates, allowing automakers to deploy new features, resolve issues, and enhance performance remotely, without requiring customers to visit a dealership. This improves customer experience, reduces maintenance costs, and minimizes vehicle downtime.

BRIDGING THE DIGITAL AND PHYSICAL WORLDS

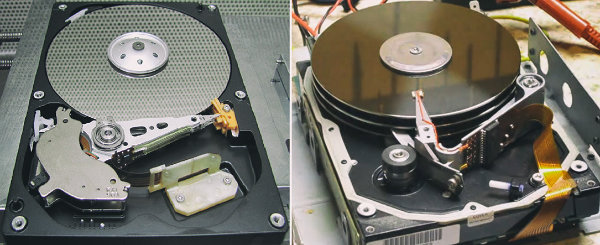

Ethernet has been a cornerstone of digital communication for decades, with IEEE® specifications published over 40 years ago. Traditionally, it was used for transferring large volumes of data between computers. However, the interface between the digital computing environment and the physical automotive world remained hardware-dependent and domain-specific. To address this gap, 10BASE-T1S Ethernet was developed.

10BASE-T1S Ethernet employs a multidrop bus architecture, utilizing a single pair of wires as a backbone. Sensors and actuators connect directly to this wire, eliminating the need for Ethernet switches to link multiple devices. When data needs to be transmitted to higher-speed interconnections, a simple switch with a 10BASE-T1S port and higher-speed ports facilitates the transfer. Because every device on an Ethernet network uses the same frame format, there is no need for specialized translation gateways.

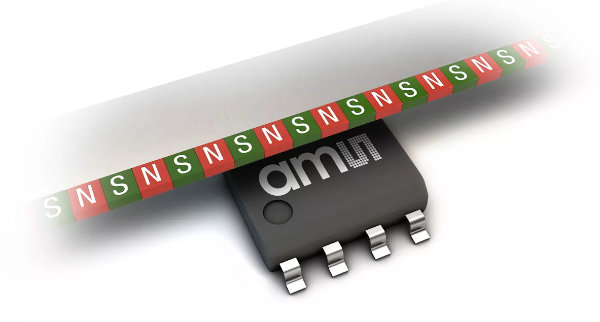

The introduction of 10BASE-T1S Ethernet represents a pivotal milestone in automotive networking. By providing a standardized and efficient means of connecting sensors and actuators, it enables real-time data exchange between digital and physical vehicle components. This technology enhances responsiveness and coordination among vehicle systems. Figure 2 illustrates the concept of zonal versus domain architectures.

Figure 2. Zonal vs. Domain Architectures.

REAL-WORLD APPLICATION: DEMONSTRATION

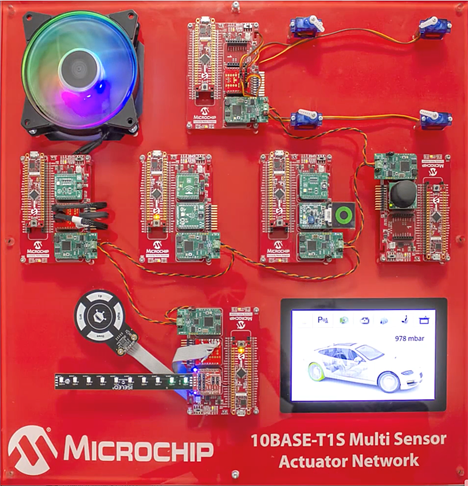

To highlight the practical benefits of 10BASE-T1S Ethernet, Microchip Technology developed a demonstration showcasing how this technology facilitates seamless communication between various sensors and actuators within a vehicle. The demonstration incorporates pressure, proximity, and light sensors, capturing real-world data that is processed by a centralized computing platform. The processed data then controls motors, fans, lights, and displays, creating a dynamic interaction between the digital and physical realms.

A video of this demonstration is available on YouTube (https://youtu.be/nD1c3eLYp7M). Figure 3 provides a visual representation of the demonstrator setup.

Figure 3. Multi-Sensor and Actuator Demonstrator.

This demonstration underscores the versatility of 10BASE-T1S Ethernet and its potential to simplify vehicle communication systems. By leveraging a single multidrop bus operating on a single pair of wires, the technology removes the need for dedicated Ethernet switches to connect multiple sensors and actuators. As data flows through the network, a simple switch with a 10BASE-T1S port can interface with higher-speed connections while preserving the standardized Ethernet frame format across the entire system.

MONUMENTAL BENEFITS FOR AUTOMAKERS

Adopting a unified protocol for most vehicle functions presents significant advantages for automakers. Traditionally, manufacturers had to support multiple application-specific standards. Each model year introduces advancements in Advanced Driver Assistance Systems (ADAS), requiring new cameras, radar, ultrasound sensors, and, in the future, lidar. Additionally, updates to infotainment and navigation systems, along with improvements in other vehicle components, often require extensive hardware changes.

Modern vehicles may contain up to 40 different wiring harnesses, dozens or even hundreds of Electronic Control Units (ECUs), and miles of cabling that can weigh up to 250 lbs. The variety of cables necessary for different applications also creates challenges related to electromagnetic compatibility (EMC), as each application has distinct requirements.

Transitioning to a unified protocol simplifies the vehicle’s internal architecture, reducing the number of wiring harnesses and ECUs required. This, in turn, decreases weight, complexity, and associated maintenance costs while enhancing reliability and overall vehicle performance.

MEETING FUTURE DEMANDS

As modern vehicles evolve, they will rely on hundreds of millions of lines of code—far surpassing today’s 100 million lines. To support this growing complexity, the industry is shifting toward an Ethernet-based zonal electronic/electrical (E/E) architecture. This approach consolidates sensors into a single link from the zonal gateway to the backbone and central computing platform.

The transition to an Ethernet-based zonal E/E architecture is essential for supporting the increasing complexity of modern vehicles. As the number of sensors, actuators, and electronic systems continues to grow, a scalable and efficient network infrastructure becomes critical. Ethernet provides the bandwidth and flexibility needed to handle the vast amounts of data generated by these systems, ensuring that the vehicle can operate smoothly and efficiently.

As the industry continues to evolve, the adoption of Ethernet-based architectures will play a crucial role in shaping the future of automotive technology, ensuring that vehicles remain connected, efficient, and innovative. What began as a concept for a unified vehicle communication architecture is now on the cusp of becoming a reality. Some vehicles on the road today already use Ethernet for their IT architecture, and models featuring the new zonal architecture that extends to the physical-digital interface will soon enter production. This approach not only simplifies vehicle design but also opens the door to new possibilities for software-driven innovation, as functions that were once defined by hardware can now be implemented and updated through software.

Virtaamamittaus on monissa laitteissa kriittinen mutta usein ongelmallinen toiminto. Perinteiset mekaaniset anturit kuluvat ja jäävät sokeiksi pienille virtausnopeuksille. Ultraäänitekniikkaan perustuvat valmiit moduulit tarjoavat nyt tarkan, huoltovapaan ja helposti integroitavan vaihtoehdon niin kuluttaja- kuin teollisuussovelluksiin.

Virtaamamittaus on monissa laitteissa kriittinen mutta usein ongelmallinen toiminto. Perinteiset mekaaniset anturit kuluvat ja jäävät sokeiksi pienille virtausnopeuksille. Ultraäänitekniikkaan perustuvat valmiit moduulit tarjoavat nyt tarkan, huoltovapaan ja helposti integroitavan vaihtoehdon niin kuluttaja- kuin teollisuussovelluksiin.