For many years now, automation in the industry has meant much more than simple robotics on the production lines. Modern solutions make possible automation of the most complex processes, in almost every branch of economy: in factories, warehouses, mines, transhipment points, ports, public infrastructure, agriculture. As what is commonly understood as automation develops, so does the need for monitoring even bigger self-operating data aggregation systems with an ever-growing number of sensors and synchronisation between multiple (diverse!) actuators. At the same time, in the face of competition on the world markets, there is a growing interest in scalable solutions, which are highly compatible and easy to modernise. That is how the so-called “Industry 4.0” emerged, based on computerisation and centralised control. Today, solutions such as machine parks controlled by a programme executed on a server or synchronised management of hundreds of devices have become a standard, and not something reserved just for big entrepreneurs. The “Internet of Things” (IoT) enables the construction of efficient and cost-effective (and thus competitive) automation systems even in small plants and farms.

Thousands of products intended for developing the latest systems of industrial control are available from the TME catalogue. Out of these products, special attention should be paid to the offer of Advantech – a Taiwanese manufacturer specialising in industrial networks and compatible controlling & monitoring modules. This manufacturer’s offer illustrates perfectly the range of possibilities brought by the fourth era of the industrial revolution. Let’s take a look at Advantech’s offer – from components for network building to a wide range of executive modules.

NETWORK INFRASTUCTURE

All Smart Factory solutions, i.e. “intelligent” machine parks based on centralized systems of data control and aggregation, use the industrial network infrastructure. Even in the case of the latest products, Ethernet and serial connections (and even Wi-Fi) and commonly used protocols, such as Modbus/TCP or RTU, remain basic communication interfaces. This is mainly because high compatibility is required. Therefore, many of Advantech’s solutions allow for communication with base modules using these standards.

Ethernet switches

Basing an automation system on the Ethernet network comes with a great advantage, namely scalability. Some of the advantages of this method are the low cost of cabling and the possibility to conduct diverse communication with the use of the same connections. Thanks to this, users can proceed with gradual modernisation of an already existing system or expand it. The simplest device for creating a network are switches – unmanageable units responsible for the distribution of data packs to the receivers. These types of devices also function as repeaters – they amplify the signal, allowing to extend the distance for wired communication.

Basing an automation system on the Ethernet network comes with a great advantage, namely scalability. Some of the advantages of this method are the low cost of cabling and the possibility to conduct diverse communication with the use of the same connections. Thanks to this, users can proceed with gradual modernisation of an already existing system or expand it. The simplest device for creating a network are switches – unmanageable units responsible for the distribution of data packs to the receivers. These types of devices also function as repeaters – they amplify the signal, allowing to extend the distance for wired communication.

Products by Advantech are adapted to be used in industrial conditions. They can operate within a wide range of supply voltages (e.g. from 12V to 48V DC), and are immune to voltage spikes. They feature robust housings for DIN rail mounting or mounted with the use of special fixtures. They are also characterised by good thermal tolerance. An additional advantage of selected models is their compatibility with the PoE technology, i.e., Power over Ethernet. Thanks to this technology, it is possible to use the transmission lines to supply power to electrical loads, which allows for significant savings, especially in the case of systems incorporating numerous terminal devices dispersed over a large area – the network installation itself allows not only to supervise the elements of the installation, but also to supply them with power.

The current understanding of industrial automation, especially the Internet of Things, isn’t of course limited to solutions for production lines control or supervising warehouses. This field also includes products used in public spaces (e.g. in collecting data on road traffic), in buildings automation, as well as in agriculture.

One of the technologies that are characteristic of IoT industrial devices is LPWAN (Low-Power Wide-Area Network), a wireless network using radio frequencies below 1 GHz. It doesn’t offer a high throughput (up to 50kb/s), but it is characterised by a great range (up to few kilometres) and very low power consumption. For example, the WISE-4210-NA access point enables a connection with 64 wireless sensors – each of which, by using the energy accumulated in a single 3.6V Li-Ion cell (AA format), can operate for even up to 5 years, transmitting information over a distance of up to 5km. WISE-4210 retrieves these data and transmits them – using Azure cloud services or a dedicated server – for further processing by the IT system.

Base modules using Wi-Fi or LTE networks offer more complex methods of wireless communication. Their great advantage is the possibility of standalone operation in data aggregation. They function by using methods of wireless transmission based on WLAN or cellular networks (in this case, they don’t require the development of their own cable infrastructure). They are dedicated to systems operating over large areas, such as container parks, photovoltaic fields or large farms. They can be used for collecting information (e.g. from metrological and energy sensors) and also controlling. They cooperate with a range of standard solutions, such as MQTT protocols or the JSON format (in which the collected data can be transmitted to a selected network service). Input/output modules are connected to a universal base device socket for control devices located at the bottom of the body. This allows for the connection of sensors or terminal devices controlled with typical signals – they are, therefore, universal and, additionally, based on open standards, providing a lot of liberty in designing the installation.

For wired networks, Advantech produces a range of modules facilitating their expansion and adaptation to specific needs. These include modular converters used for transition between popular types of signals and communication protocols, such as USB, GPIB, TTL, data transmission using optical fibre bundles. The manufacturer’s offer also includes LoRaWAN gateways (long range) and Modbus gateways, which enable the connection of devices of other standards to Ethernet networks.

Advantech also manufactures high quality (LAN and LTE) routers allowing to build distributed networks, communicating with the PBX via the Internet. These devices are enclosed in robust, metal housings, mounted on a DIN rail or directly on a wall. They can operate within a wide range of temperatures (e.g. in non-heated, remote buildings).

RS-485 modules from the ADAM-4000/4100 series

Industrial networks don’t have to be based on Ethernet connections – in many cases, it may be more cost-effective to choose proven, industrial standards. The ADAM-4000/4200/4500 series is an example of Advantech modules designed for high compatibility. It uses the RS-485 serial bus for communication and allows for remote management of input/output ports using different technologies (depending on the model). These types of solutions provide analogue and digital inputs/outputs, they are also available in a form of a repeaters increasing the maximum length of the transmission line, counters, as well as converters supporting RS-232, RS-422 and USB standards and even fibre optic communication.

Industrial networks don’t have to be based on Ethernet connections – in many cases, it may be more cost-effective to choose proven, industrial standards. The ADAM-4000/4200/4500 series is an example of Advantech modules designed for high compatibility. It uses the RS-485 serial bus for communication and allows for remote management of input/output ports using different technologies (depending on the model). These types of solutions provide analogue and digital inputs/outputs, they are also available in a form of a repeaters increasing the maximum length of the transmission line, counters, as well as converters supporting RS-232, RS-422 and USB standards and even fibre optic communication.

The latter, in this case, doesn’t ensure faster data transmission, but routing the signal through the light beam medium protects the transmission against any electromagnetic interference, which is a significant advantage for installations in power distribution companies or those laid where in the presence of significant industrial inductive loads. The ADAM-4500 series also includes server serial ports (2 or 3 ports), whose task is to connect the RS-485 devices to infrastructure based on Ethernet network.

INDUSTRIAL COMPUTERS

Of course, popular phrases such as “Industry 4.0” and Smart Factory are mostly associated with computerisation. It’s not always correct, as IoT solutions are based primarily on the use of autonomous modules. Nevertheless, a computer, or a program running on a remote server or in the cloud, is usually used to manage the entire system, or at least supervise its operation. Industrial computers are often used to directly supervise the operation of machines, collect data from sensors, etc. One of the advantages of such a solution is its flexibility – using such a computer is simple (it doesn’t have to be different than working with a regular laptop), and its software (due to availability of libraries and drivers) is surely within the competence of any IT engineer, as it doesn’t require profound knowledge of specific manufacturer’s own solutions.

Of course, popular phrases such as “Industry 4.0” and Smart Factory are mostly associated with computerisation. It’s not always correct, as IoT solutions are based primarily on the use of autonomous modules. Nevertheless, a computer, or a program running on a remote server or in the cloud, is usually used to manage the entire system, or at least supervise its operation. Industrial computers are often used to directly supervise the operation of machines, collect data from sensors, etc. One of the advantages of such a solution is its flexibility – using such a computer is simple (it doesn’t have to be different than working with a regular laptop), and its software (due to availability of libraries and drivers) is surely within the competence of any IT engineer, as it doesn’t require profound knowledge of specific manufacturer’s own solutions.

Industrial computers by Advantech are compact units powered by 64-bit architecture processors, Intel Core and Intel Atom series. This ensures their high compatibility – they support Windows (the manufacturer recommends using Windows 10) and Linux – here, it’s recommended to use the manufacturer’s own version, AdvLinux, based on popular Ubuntu distribution. These computers are equipped with typical industrial ports, such as a GPIO connector for CAN bus, RS-232 and RS-285 bus, Ethernet, USB 3.0 and HDMI/DisplayPort sockets, as well as wireless communication modules (configuration depends on the model). These are miniaturised products, enclosed in housings equipped with a ribbed lid (acting as a heat sink) and cooled passively. Requirements related to the power line depend on the selected product, for some of them it will be only 12V DC, while others operate within a wide range of voltages (e.g. from 10V to 30V DC). Advantech produces also touchscreens equipped with HDMI/DP/VGA inputs. They can be used to build intuitive, complex machine interfaces – they can be effectively applied in industrial conditions, thanks to their high ingress protection rating (IP66) and mechanical resistance. They are available in variants with the diagonal from 12.1 inches to 21.5 inches.

USB modules – hubs, signal inputs and outputs

The question arises – how can compact industrial computers like the ones described above be connected to sensors, controllers, etc.? Well, it’s easier than it seems.

USB, although it remains a communication standard associated primarily with the consumer market, is widely used in industrial networks. It is popular due to its versatility and high connection speed. With the use of the input-output modules of the USB-4700 series, integrating the computer with the automation system is as easy as connecting a regular printer. Moreover, the products in this group have a complex functionality: they provide analogue and digital I/O lines, as well as counter channels. They are powered directly from the USB interface. The installation can be expanded with the use of USB-4600 series hubs.

USB, although it remains a communication standard associated primarily with the consumer market, is widely used in industrial networks. It is popular due to its versatility and high connection speed. With the use of the input-output modules of the USB-4700 series, integrating the computer with the automation system is as easy as connecting a regular printer. Moreover, the products in this group have a complex functionality: they provide analogue and digital I/O lines, as well as counter channels. They are powered directly from the USB interface. The installation can be expanded with the use of USB-4600 series hubs.

All these products are equipped with screw clamp terminals, guaranteeing robust connection between the cable and the module, even in the case of shock or vibrations. The signal lines are routed to terminal blocks; the housings themselves can be installed using wall or VESA mounting brackets. Similarly as in the case of the above-described solutions, an important advantage of Advantech USB interfaces and hubs is their high tolerance for difficult working conditions, not only mechanical but also environmental, e.g. temperatures from -20°C to 70°C, as well as air humidity up to 95%.

PCI interface card

Of course, a “regular” computer/server, based on any selected motherboard, processor and other components, can be used as an industrial controller. Advantech offers many solutions thanks to which such a device can be adapted to work with industrial components of the automated system. PCI and PCI Express interface cardsare provided for that purpose.

Analogue input cards from the PCI-1700 and PCIE-1800 series offer sampling rates as fast as 125Msps (which means 125 million samples per second) and 12- or 16-bit resolution. In the case of applications requiring data aggregation based on a vast number of signals, it’s worth considering PCI-1713U cards, which, even though they feature lower sampling rate (100ksps), support up to 32 analogue lines. The card is connected to a clamp terminal mounted on a DIN rail via single, multicore D-Sub wire – in this way, the computer can be easily disconnected from the controlled machine, which speeds up the maintenance works, even in the case of a complex control installation. Analogue output cards, which allow to control up to 32 standalone receivers, are also available at TME. Additionally, the PCIE-1800 series also includes signal acquisition extension modules, characterised by high, 24-bit resolution, dedicated to devices which measure vibrations or analyse data from acoustic sensors.

Aside from the products mentioned above, Advantech offers input cards and digital input/output cards, including circuits equipped with isolating components. These products can be used to support from 8 to 64 GPIO lines and operate within different voltage ranges (even with 5...40V DC signals). Moreover, they are available in relay variants, allowing to control relatively high loads (e.g. 2A, 250V AC) directly form the PCI slot of a computer. It should be noted that DIN rail-mounted terminal blocks are available for most of the products described above.

Motherboards, even the server ones, offered on the market are rarely equipped with serial bus connectors and ports of other industrial standards, unless they are explicitly dedicated to industrial applications. That’s where Advantech solutions also come in handy. The manufacturer’s range of PCI cards includes adapters equipped with RS232/RS422/RS485 serial ports, enabling isolated connection to the CAN network and GPIB interface lines. Another example of a typical industrial component, which can become an extension of any PC computer, are PCI circuits equipped with 8 channels of 16- or 32-bit counters. Hardware support of high frequency signals and the possibility to generate configurable interrupts will be a desirable function for complex controllers operating in real-time. It will allow to relieve the CPU load, and thus execute more efficient automation programs. The multifunction PCI/PCI-E cards serve the same purpose. They were designed for high compatibility and systems requiring the operation of non-standard signals. These products are equipped with counters, converters (ADC and DAC), and also FIFO memory.

It’s worth noting here that the multifunctional expansion cards are available also in the PC/104 standard. This compact PC system format allows for daisy-chaining of successive modules (by stacking them one on top of the other) and is frequently used for installations with limited space.

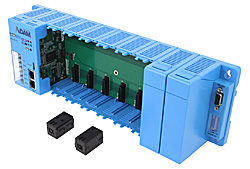

ADAM-5000 controller series

Of course, an industrial computer used to control a single machine or a limited set of sensors/receivers, doesn’t need to have a huge computing power – especially if its purpose is to perform a function that could be effectively performed by a set of monitoring components placed in a control cabinet. On the other hand, it’s easier to reprogramme (and even modernise or expand) a computer – that’s why it’s an attractive alternative for a controller of industrial processes. To combine the best of both these words, i.e. adaptability and the compact/modular design, Advantech has developed the ADAM-5000 series. These are autonomous units based on Cortex M4 processors.

Of course, an industrial computer used to control a single machine or a limited set of sensors/receivers, doesn’t need to have a huge computing power – especially if its purpose is to perform a function that could be effectively performed by a set of monitoring components placed in a control cabinet. On the other hand, it’s easier to reprogramme (and even modernise or expand) a computer – that’s why it’s an attractive alternative for a controller of industrial processes. To combine the best of both these words, i.e. adaptability and the compact/modular design, Advantech has developed the ADAM-5000 series. These are autonomous units based on Cortex M4 processors.

The core of the device is an integrated motherboard, placed in a compact enclosure, equipped with the CPU, operational memory, Ethernet ports and DB9 connectors for RS-232 and RS-485 interfaces (the unit offers native support for the Modbus protocol). The body of the controller has mounting and ventilation holes. It is a full housing with sockets for expansion cards (e.g. analogue and digital inputs/outputs, etc.). When the desired modules are mounted and unused slots are covered, we get a controller adapted to our needs – fully configurable and programmable, expandable, and at the same time adapted to mounting in machine park conditions.

STANDALONE AND COOPERATIVE MODULES

Products described above are intended for creating complex solutions, extensive modernisation or completely new control systems. In reality, implementing network solutions is not always possible on a mass scale. The same is true for the expansion of control systems, even if they have been based on the Ethernet or serial infrastructure from the very beginning. That’s why Advantech offers a series of smaller modules with strictly defined functions. These devices can be incorporated in the system at any moment, for example to gradually modernise it.

Isolation modules

The challenge posed to industrial network contractors by the industrial environment is the relatively high risk of breakdowns, voltage spikes and disturbances caused by inductive loads, such as engines, etc. A single pulse propagated through the installation can lead to many troublesome and expensive malfunctions. That’s where ADAM-3000 modules, which perform an isolation function, come in handy, as they separate the network from potential hazards. These products are designed to support resistance temperature detectors (RTD), thermocouples and analogue lines (operating in the minimum range of up to 10mV and maximum up to 10V, also in symmetrical variants).

The challenge posed to industrial network contractors by the industrial environment is the relatively high risk of breakdowns, voltage spikes and disturbances caused by inductive loads, such as engines, etc. A single pulse propagated through the installation can lead to many troublesome and expensive malfunctions. That’s where ADAM-3000 modules, which perform an isolation function, come in handy, as they separate the network from potential hazards. These products are designed to support resistance temperature detectors (RTD), thermocouples and analogue lines (operating in the minimum range of up to 10mV and maximum up to 10V, also in symmetrical variants).

Apart from isolation components, the manufacturer’s offer also includes a series of modules designed for communication with various automation components. These are, among others, PID controllers, digital and analogue inputs/outputs or counters using Ethernet infrastructure.

AMAX-5000 series

One of Advantech’s more advanced solutions are the compact, programmable controllers from the AMAX-5000 series. They were designed to enable the construction of complex controllers supporting the EtherCAT protocol – i.e., operating in real-time – characterised by their compact construction and a DIN rail mounting option. Any unit connected to the same network can perform the monitoring function. Data transmission is supported by the AMAX-5074 coupler equipped with RJ-45 sockets. Other input/output modules located next to it on the DIN rail are connected to this device (using a dedicated connector on the side of the body). Such a modular design of the controller enables construction of complex, customised machine controllers. The products are equipped with spring-loaded terminal blocks, which makes wire installation even easier.

Customers interested in the EtherCAT protocol should also consider the AMAX-4000 series. This group includes DIN rail-mounted digital input and output modules (also isolated ones) – these products enable simple, step-by-step implementation of IoT solutions or remote control in an automation system.

Text prepared by Transfer Multisort Elektronik Sp. z o.o.

Virtaamamittaus on monissa laitteissa kriittinen mutta usein ongelmallinen toiminto. Perinteiset mekaaniset anturit kuluvat ja jäävät sokeiksi pienille virtausnopeuksille. Ultraäänitekniikkaan perustuvat valmiit moduulit tarjoavat nyt tarkan, huoltovapaan ja helposti integroitavan vaihtoehdon niin kuluttaja- kuin teollisuussovelluksiin.

Virtaamamittaus on monissa laitteissa kriittinen mutta usein ongelmallinen toiminto. Perinteiset mekaaniset anturit kuluvat ja jäävät sokeiksi pienille virtausnopeuksille. Ultraäänitekniikkaan perustuvat valmiit moduulit tarjoavat nyt tarkan, huoltovapaan ja helposti integroitavan vaihtoehdon niin kuluttaja- kuin teollisuussovelluksiin.